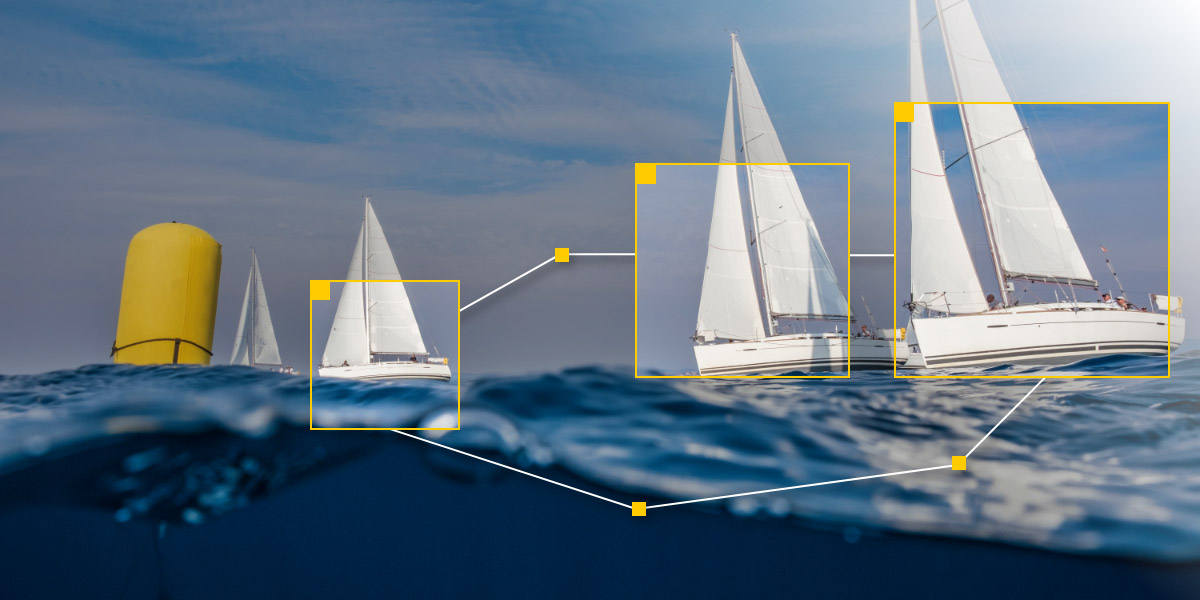

It's Time to Set Sail: The Future of Automation Has Begun

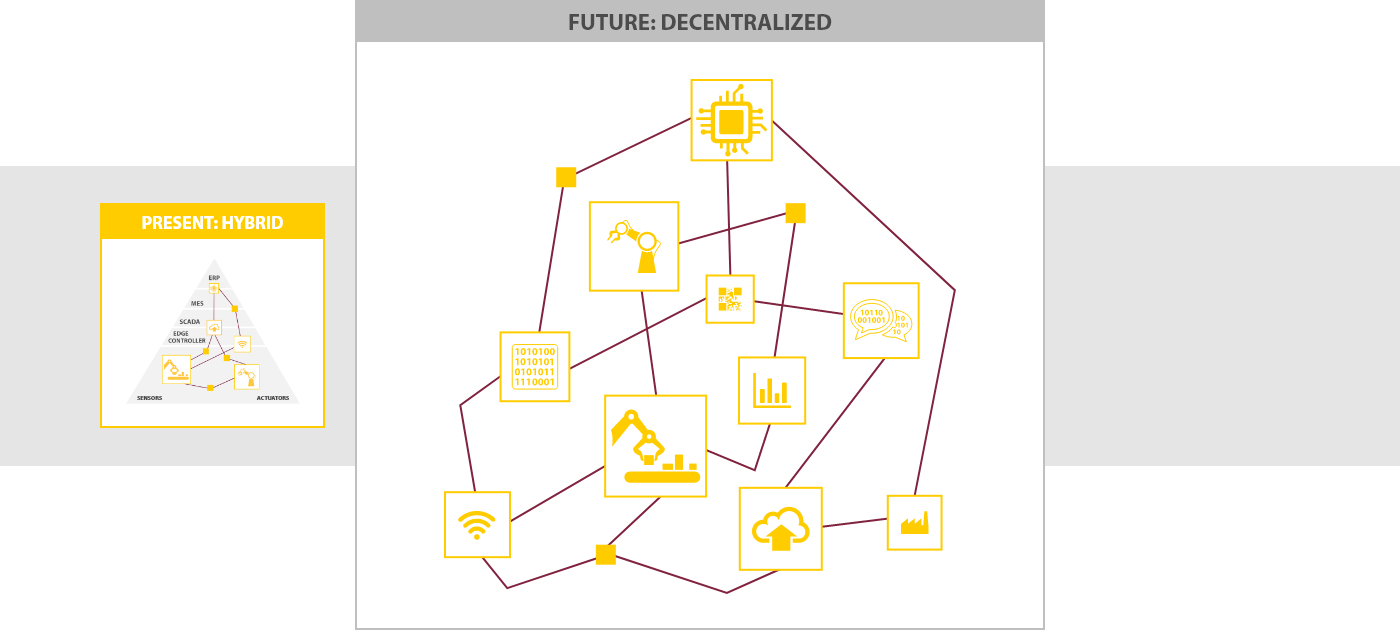

A well-established team of competent individuals often works more efficiently than a strictly hierarchical organization. If each person understands their job and the ultimate goal, central management does not have to decide everything on its own.

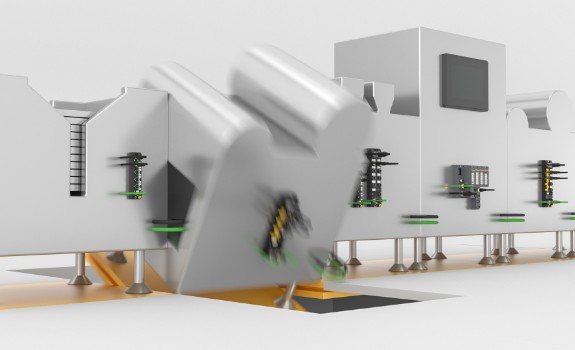

Efficiently automated machines and plants minimize costs, safeguard product quality and guarantee high availability for production. Break down rigid hierarchies and shift responsibilities to local components. Decentralized automation also reduces commissioning and time-to-market while simplifying the expansion or movement of production resources. Modularize your plants and machines — this will give you new degrees of freedom in production.

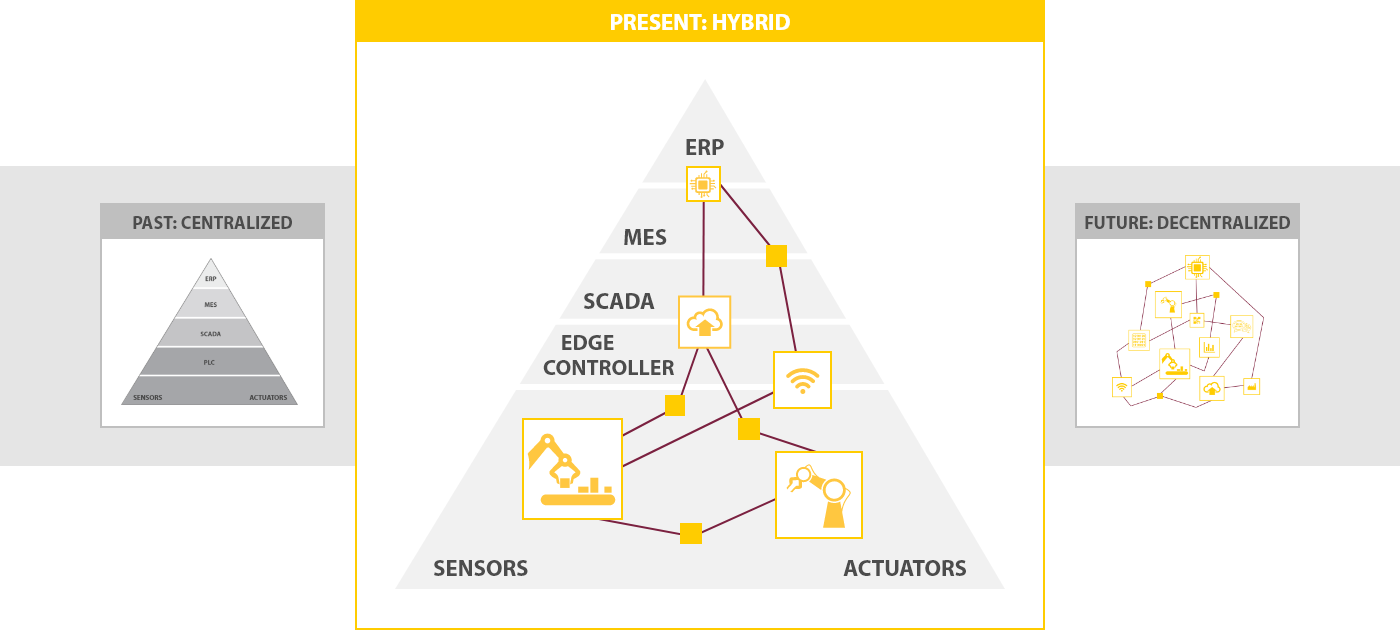

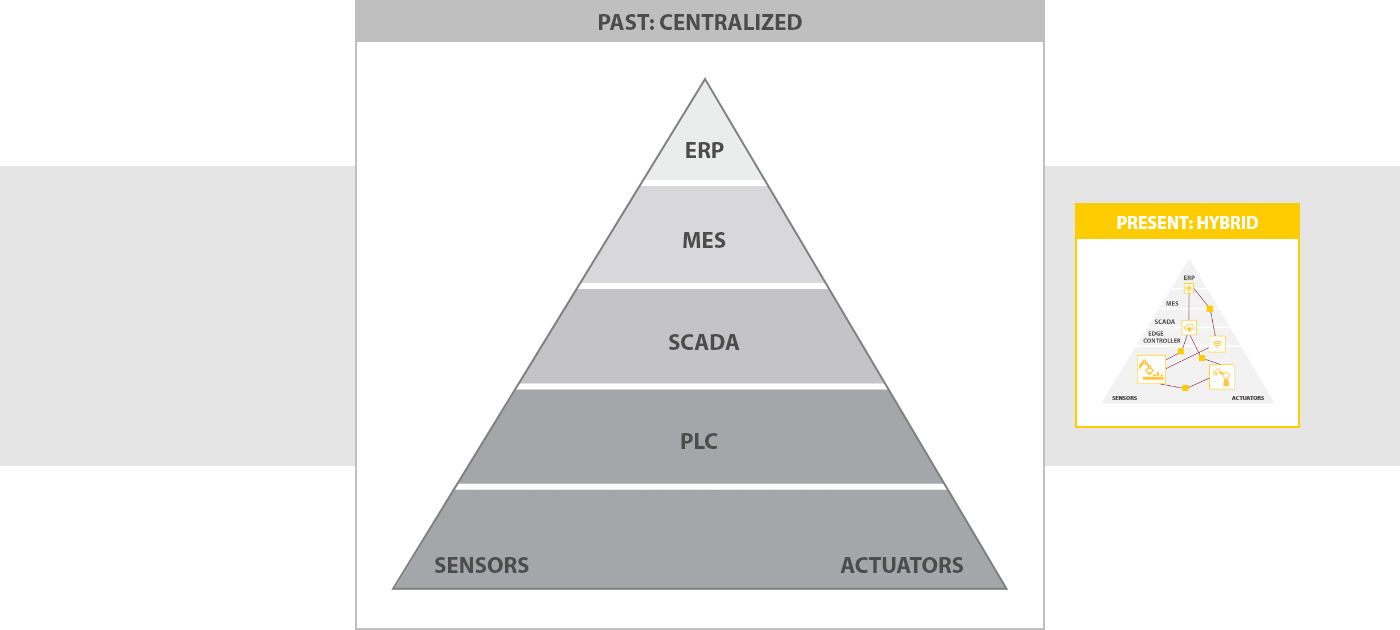

Automation has been dominated by hierarchies and long decision-making paths, but the levels are becoming increasingly permeable.

You can now utilize sensors that detect machine wear, RFID tags that tell the machine whether it is correctly configured for the next step and what it has to do, or an I/O module that decides independently to operate an actuator. It is no longer possible to place the present and future of automation at the levels of the classic automation pyramid. Decentralized preprocessing reduces machine data to valuable information and thus lays the foundation for a new era of automation.

Dive Deeper with our Whitepaper "Modular Plant Concepts"

The whitepaper surveys the world of decentralized automation and shows the opportunities offered by decentralized solutions in mechanical engineering and logistics.

Three Fields of Application for Decentralized Automation

Shipshape: Decentralized Automation in Practice

Turck moved toward decentralized automation at an early stage. Many customers have already discovered the benefits of decentralized solutions — here is a small selection of success stories.

Ready to Weather Any Storm: Products for Decentralized Automation

In general, any product can be used in centralized or decentralized architectures. However, Turck has some innovative products that make decentralized solutions much easier.

CODESYS Controls

PLCs with CODESYS are ideal for modular machines since the open control software also enables modular control programs to be set up. You will also benefit from the experience and work results of the CODESYS community.

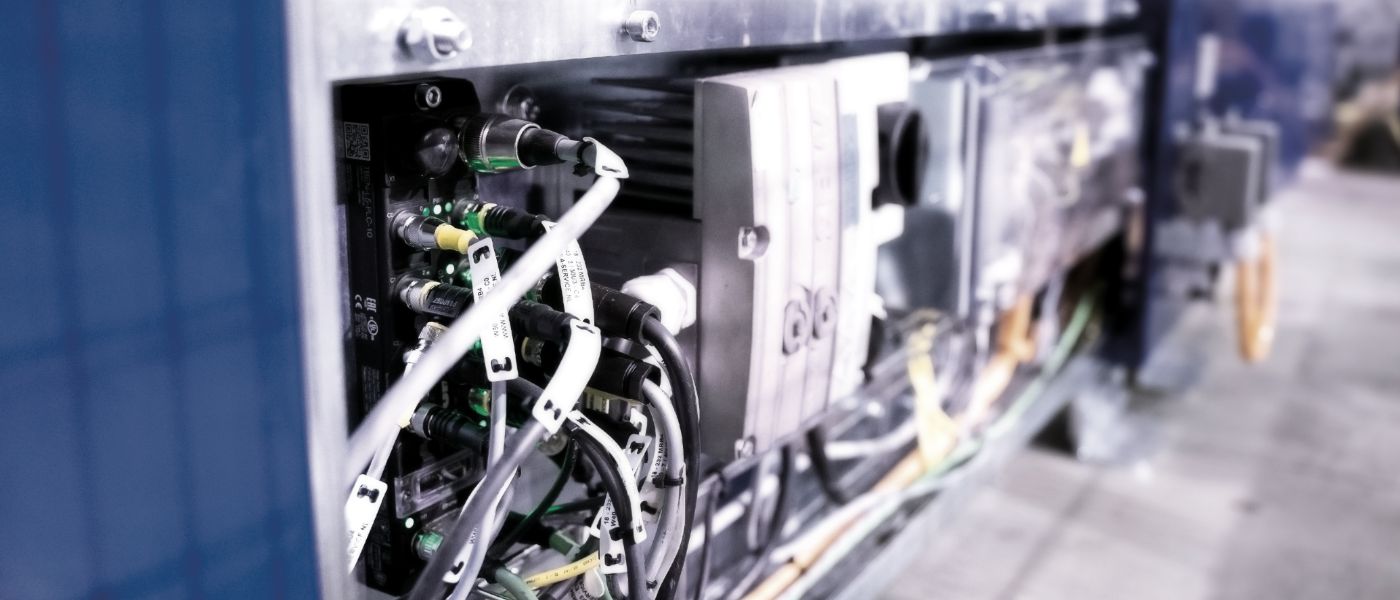

I/O Modules with Logical Control Function

All I/O modules with Turck multiprotocol Ethernet are equipped with logical control capability. The ARGEE programming interface is used to program control functions on the module — without writing program code, at no additional cost.

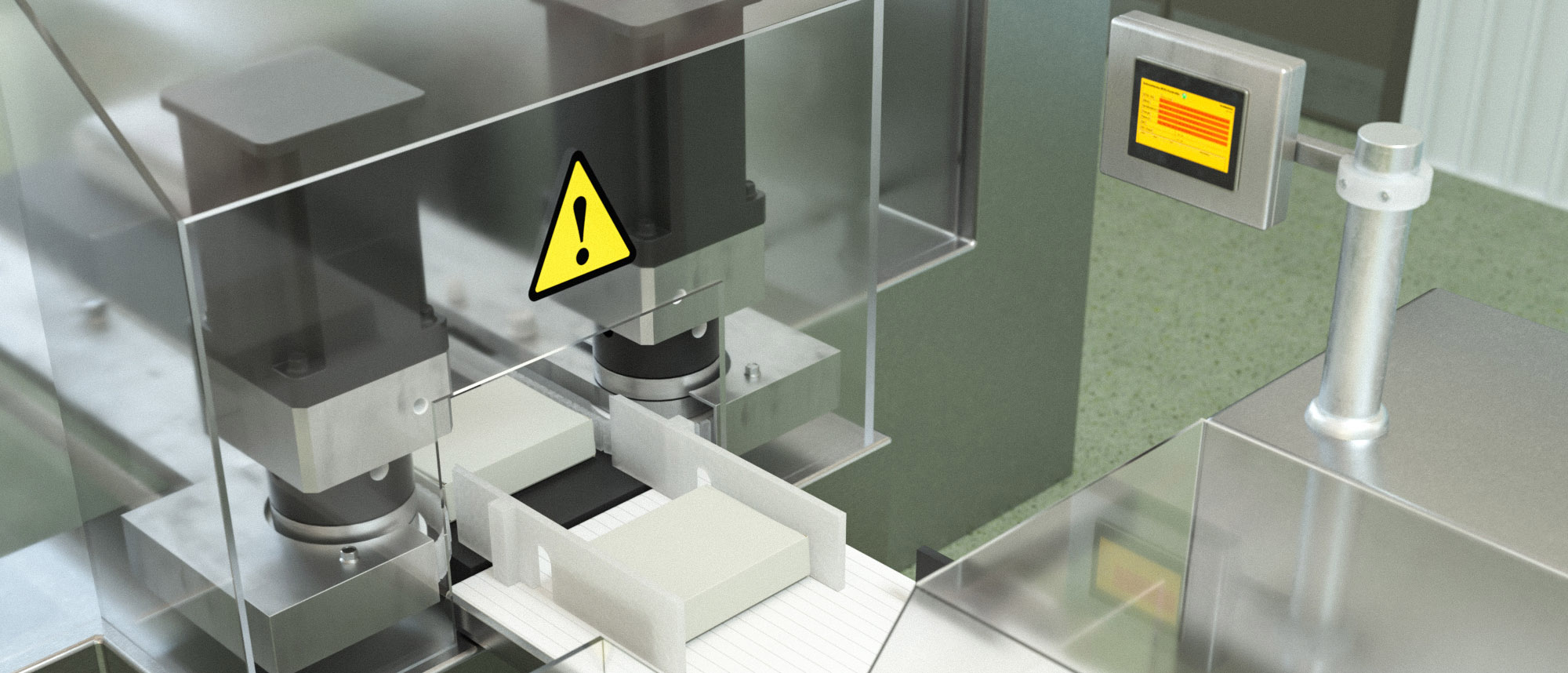

Safety Modules with Integrated Safety Controller

IP67 block I/Os enable safety functions to be implemented without control cabinets. Safety applications can be tested offline with their safety controller and controlled in a decentralized way during live operation.

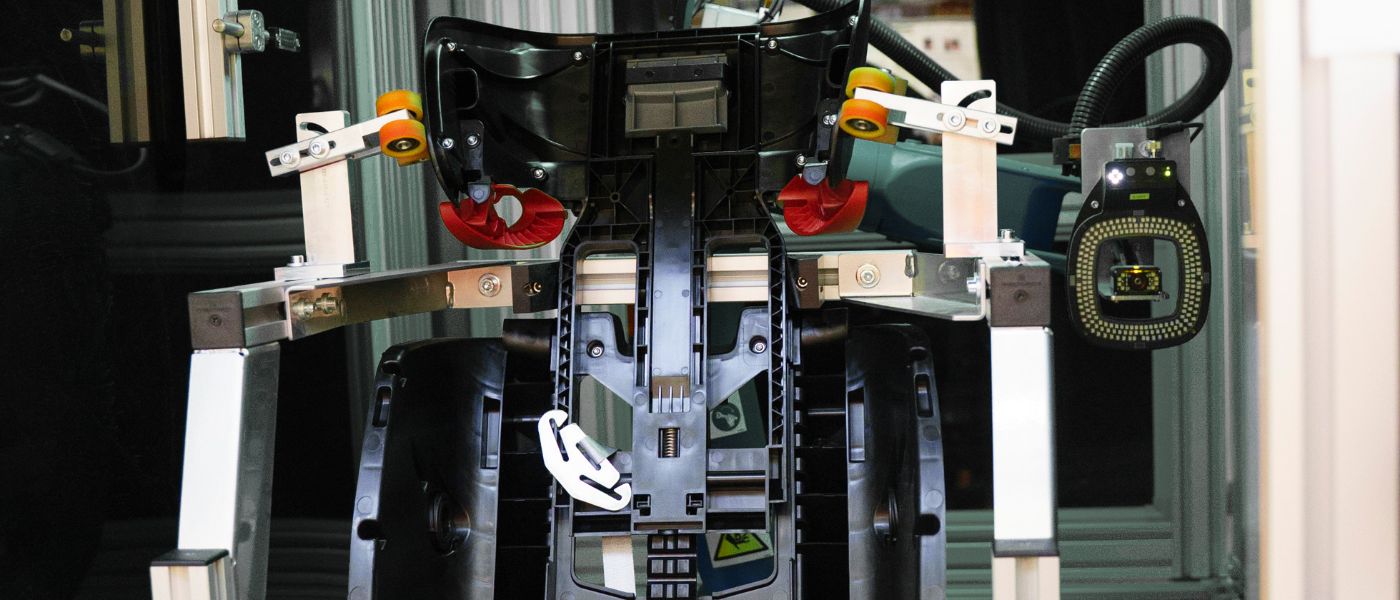

RFID Read/Write Heads and Interfaces

Whether in a control box or directly in the field as a complete IP67 system: RFID technology can decentralize decision-making and information, contributing to greater flexibility and process security.

IO-Link Products

Turck's IO-Link portfolio is impressively comprehensive. As a full provider of both the device and the master side, Turck guarantees easy integration of the IO-Link devices into the control environment.

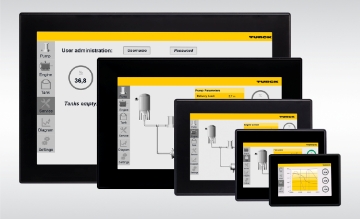

HMI Control Devices

HMI input systems are used if information needs to be visualized at the machine and commands need to be entered. The TX100, 500 and 700 series offer an impressive range of interfaces without extra costs for licenses of the visualization software.

Set the sails towards decentralized automation

Contact us and we will identify with you the potential of decentralized concepts for your production.