Highly Available Ethernet in ATEX zone 1

excom Ethernet gateway GEN-2G minimizes wiring effort in lithium ion battery production

Challenge

In lithium-ion battery production, process steps such as electrolyte filling and coating involve explosive atmospheres. Nevertheless, numerous sensors and actuators must be reliably connected in these hazardous areas. Traditional point-to-point wiring leads to high installation effort and complicates maintenance. Additionally, space in control cabinets is extremely limited. Operators require an I/O solution that reduces wiring, ensures secure communication, simplifies diagnostics and process optimization, and complies with international Ex certifications.

Your Benefits

- Time savings thanks to minimal wiring effort

- High system availability through various redundancy concepts

- Future-proof: parallel data communication for IIoT, monitoring and diagnostics—even in Zone 1

- Easy maintenance and diagnostics via multiprotocol Ethernet

Solution

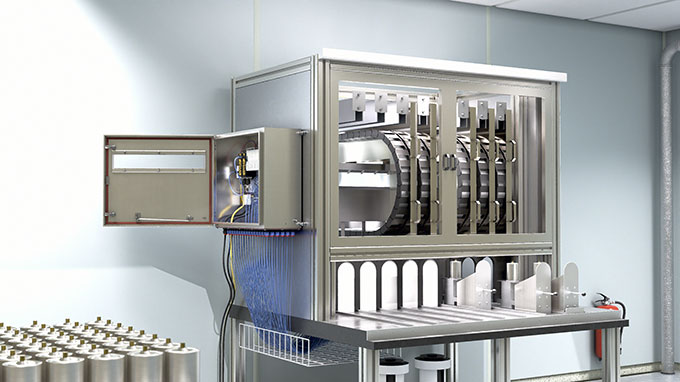

TURCK’s remote I/O system excom for ATEX Zone 1 transmits signals from intrinsically safe sensors and actuators in Zones 0 and 1 via Ethernet to the higher-level controller. Communication between the non-Ex and Ex areas is handled via fiber optics using TURCK’s media converters FOCEN11Ex-2G and FOCEN11-3G—across distances of up to 2,500 m. From this point, multiple excom stations can be integrated using the GEN-2G Ethernet Gateway over copper cables and communicate via PROFINET, EtherNet/IP or Modbus TCP.

Users deploy the compact MT08-2G module carrier with the GEN-2G Ethernet Gateway. From there, data is transmitted via Ethernet to the production line controller. All excom components are certified for use in hazardous areas and can be installed in compact cabinets to save space. Integrated diagnostic functions provide status and process data. Thanks to multiprotocol support, this data can be transmitted in parallel over the same line, ensuring maximum security for process data communication. excom is considered the most compact I/O system of its kind. No other redundant I/O system for Ex areas can connect up to 960 signals in a standard control cabinet.

Further Information

- Link to the Product: GEN-2G Gateway for Zone 1

- Link to the Products: FOCEN11Ex-2G and FOCEN11-3G Media Converters

- Link to the Product – Ethernet Gateway GEN-2G

- Link to the Product – Fiber-Optic Ethernet Media Converter for Zone 1

- Link to the Product: Module Rack for Eight Modules MT08-2G

- At a Glance: Safe Use of Ethernet in Ex Areas

- Technology Page: Ethernet in Hazardous Locations

- Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

- RFID

- Snap Signal

- Sustainability

- The Visual Factory

-turck-image.jpg)

-turck-thumbnail.jpg)